Crown & Bridge

Full-Cast Crown - Non-Precious (Flat Fee)

Full-Cast Crown + Metal Fee

Noble/High Noble:

(Pd 24.96%, Ag 70%, Noble, White Color)

(Au 1.9%, Pd 80.2%, Noble, White Color)

(Au 40%, Ag 45.7%, Noble, Yellow Color)

(Au 58%, Ag 27%, High Noble, Yellow Color)

PFM Crown - Non-Precious (Flat Fee)

PFM Crown + Metal Fee

Noble/High Noble:

(Pd 25%, Co 42.75%, Noble, White Color, Flat Fee)

(Au 1.9%, Pd 80.2%, Noble, White Color)

(Au 86.5%, Pt 10.4%, High Noble, Yellow Color)

K-Fast Crowns

K-Fast is a one, two or three day crown service. The K-Fast crown is ideal for the patient that does not want to wait the typical seven to ten days for their restoration to be processed.

To start a K-Fast crown just call Kaylor Dental Lab., Inc. at 316-943-3226 or 1-800-657-2549 to schedule your case

The K-Fast crown can be a single unit up to a six unit bridge.

-

One Day K-Fast porcelain to NBF metal

-

One Day K-Fast full cast

-

Two Day K-Fast porcelain to NBF metal

-

Two Day K-Fast full cast

-

Three Day K-Fast porcelain to NBF metal

-

Three Day K-Fast full cast

The Three Day K-Fast crown is perfect for crown under partial restorations for an additional fee.

Overnight shipping is available for an additional fee.

Preparation

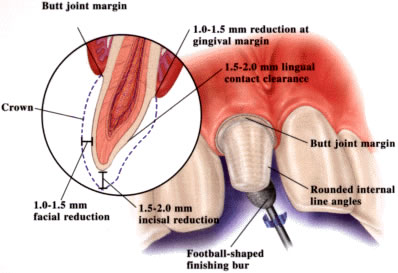

Facial Enamel Reduction

0.6 mm depth cuts are made to establish a uniform preparation and porcelain

Uniform Facial Preparation

A medium grit rounded diamond bur is used to remove a uniform thickness of facial enamel by joining the depth-cut groves

Uniform Facial Preparation

The depth of the grooves are joined in three planes by angling the diamond bur to the corresponding gingival, middle, or incisal plane of the tooth.

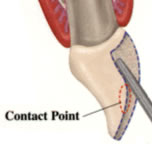

Chamfer Margins

Correct preparation of the chamfer margins interproximally allow the appropriate bulk of porcelain.

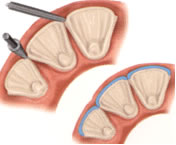

Interproximal Extention

Using the same diamond bur, the interproximal preparation is extended from the gingival chamfer into the proximal space.

Incisal Preparation

The diamond bur is angled to bevel back the incisal edge.

Linqual Reduction to Increase Length

The diamond bur is angled to eliminate undercuts and establish a deep chamfer on the lingual aspect of the preparation to ensure a passive fit. The incisal should be rounded. Avoid sharp line angles.

Anterior Crown Preparation

Posterior Crown Preparation

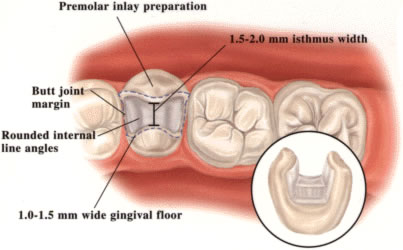

Premolar Inlay Preparation

Molar Onlay Preparation